- Change theme

Advanced PCB Solutions: Driving Innovation in Telecommunications and Robotics

Printed Circuit Boards (PCBs) serve as the backbone of innovation, enabling compact, high-performance devices across various industries.

09:14 23 April 2025

Mastering PCB Fabrication, Assembly, and Components for Next-Gen Electronic Applications

In the rapidly evolving world of electronics, Printed Circuit Boards (PCBs) serve as the backbone of innovation, enabling compact, high-performance devices across various industries. From conceptual design to production, the processes of PCB fabrication, assembly, and component integration require precision engineering, material expertise, and cutting-edge technology.

PCB Fabrication: Precision at Every Layer

PCB fabrication involves the creation of multi-layered structures that interconnect and support electronic components. Modern fabrication facilities leverage automated CAM systems, laser direct imaging (LDI), and controlled impedance technologies to deliver highly reliable boards. For demanding applications, High-Frequency PCBs—designed with materials like Rogers or Teflon—ensure signal integrity and minimal loss at high speeds, making them ideal for RF, microwave, and high-speed digital applications.

PCB Assembly: From Bare Board to Functional Module

Once fabricated, the assembly process transforms bare PCB manufacturer into complete, functional systems. This includes surface-mount technology (SMT) and through-hole component mounting, supported by automated pick-and-place machines, reflow soldering, and automated optical inspection (AOI). Attention to thermal management, trace routing, and power integrity is crucial during this phase to ensure optimal performance and durability in the final product.

Advanced PCB Technologies: Rigid-Flex and Beyond

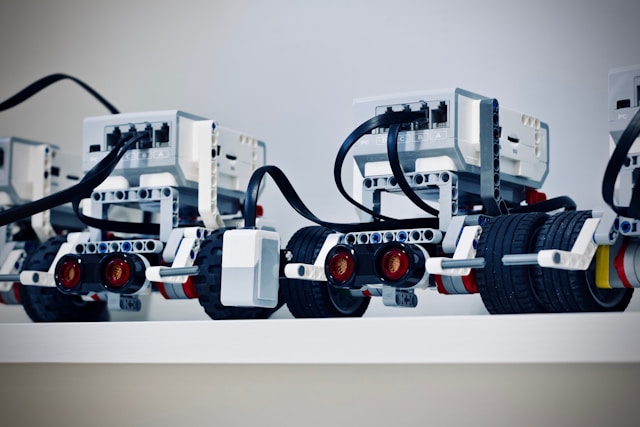

Among the most advanced solutions available today are Rigid-Flex PCBs, which combine the mechanical stability of rigid boards with the flexibility of flex circuits. These are essential in compact and dynamic environments such as robotic arms, wearable electronics, and medical implants, offering design freedom, weight reduction, and enhanced durability.

Additionally, HDI (High-Density Interconnect) and multi-layer PCBs with microvias and blind/buried vias are enabling higher functionality in smaller footprints, critical for applications in aerospace, defense, and telecommunications.

Electronic Components: The Core of Smart Functionality

High-performance PCBs are only as good as the components they host. Sourcing reliable, RoHS-compliant, and application-specific components—from microcontrollers and sensors to high-speed connectors and ICs—is integral to system efficiency. Integration of IoT modules, AI processors, and MEMS sensors has further expanded the scope of PCB applications in smart devices and intelligent automation.

Applications Across Industries: Telecommunications and Robotics

In telecommunications, high-frequency and multi-layer PCBs are foundational for base stations, satellite systems, and 5G infrastructure, ensuring high-speed data transmission and minimal latency. In robotics, Rigid-Flex PCBs provide the compact, durable, and adaptable frameworks required for autonomous movement, AI-driven control, and real-time processing in dynamic environments.