- Change theme

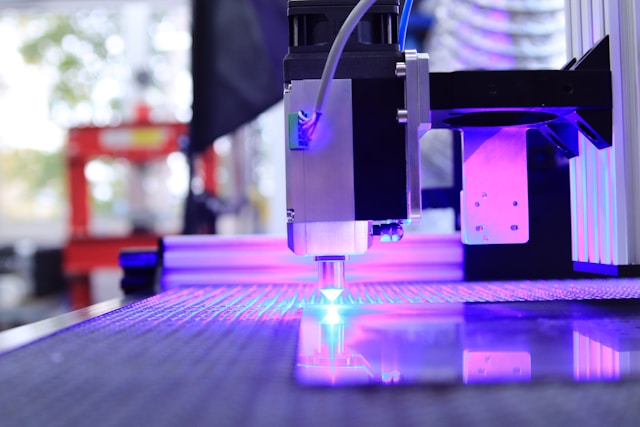

CNC Laser Cutting for Custom Plastic Parts Explained

Explore how CNC laser cutting delivers precise, custom plastic parts, boosting efficiency, accuracy, and versatility across a wide range of industries

09:24 23 April 2025

In today’s manufacturing landscape, CNC laser cutting for plastics stands out as an incredibly precise and efficient method for producing custom plastic parts. Whether you’re working on a small-scale DIY project or a large industrial application, this technology offers unparalleled accuracy and versatility. Let’s dive into how this process works and why it might be the right solution for your next project.

What Is CNC Laser Cutting?

CNC (Computer Numerical Control) laser cutting is a process that uses a focused laser beam to cut, engrave, or mark materials with precision. For plastics, this method provides clean, sharp edges with minimal waste and high repeatability. Unlike traditional mechanical cutting methods, CNC laser cutting doesn’t require physical tools to contact the material, which reduces wear and tear, improving efficiency.

How Does CNC Laser Cutting Work?

The laser-cutting machine is controlled by a computer, which interprets the design files and guides the laser along precise paths. A powerful laser beam melts or burns the plastic, enabling intricate designs and patterns. Thus, CNC laser cutting for plastics is ideal for creating parts that require tight tolerances, such as custom signage, architectural features, or even components for electronics.

Benefits of CNC Laser Cutting for Plastics

One of the primary advantages of CNC laser cutting is its ability to handle custom plastic parts with extreme accuracy. The process doesn’t rely on physical cutting tools, reducing the risk of distortion or errors during production. Here are some key benefits:

- Precision and Accuracy: The laser cutting process offers superior accuracy, capable of producing intricate shapes and fine details that would be difficult to achieve with traditional cutting methods.

- Clean Edges: CNC laser cutting creates smooth, polished edges on plastic parts, reducing the need for additional finishing processes. This is especially important for aesthetic applications such as custom displays or décor.

- Minimal Waste: The laser beam is highly focused, meaning there’s less material waste compared to traditional cutting methods. This makes it a more cost-effective and eco-friendly option.

- Versatility: CNC laser cutting can work with a wide variety of plastics, from thin acrylic sheets to thicker polycarbonate materials. This flexibility makes it an ideal choice for industries ranging from signage and retail to construction and engineering.

Common Applications of CNC Laser Cutting for Custom Plastics

CNC laser cutting has become an indispensable tool in many industries due to its ability to produce precise, high-quality custom plastic parts. Some common applications include:

- Signage and Display: Many businesses use CNC laser cutting to create custom logos, signage, and display stands from materials like acrylic. This ensures that the designs are clear and impactful, with precise cuts that enhance the overall appearance.

- Automotive and Aerospace: In sectors requiring high-performance parts, such as automotive and aerospace, CNC laser cutting ensures that components are made to exact specifications, enhancing both safety and efficiency.

- Architectural Features: Whether it’s custom plastic panels or intricate design elements for interior spaces, CNC laser cutting provides the flexibility to produce innovative architectural features with precision.

Is CNC Laser Cutting Right for Your Project?

CNC laser cutting offers speed, precision, and flexibility for high-quality custom plastic parts. Whether for DIY projects or mass production, it ensures exceptional results. This technique transforms workflows, reduces material waste, and delivers parts that meet your exact specifications, making it an ideal solution for various applications.