- Change theme

Your Ultimate 2025 Guide to Finding Every Manual And Complete PDF parts Catalog

Equipment downtime can be reduced by 73% when users have access to the necessary technical documentation.

16:53 03 June 2025

Equipment downtime can be reduced by 73% when users have access to the necessary technical documentation, which includes PDF parts diagrams.

The possibility of achieving short repair times in breakdown situations depends on whether you can obtain precise part information and technical drawings promptly.

Over several years, I have been searching through outdated paper manuals and unsatisfactory digital resources, as well as manufacturer websites.

The data show that 73% of equipment downtime would not occur if people had proper technical manuals and parts diagrams readily available.

The speed at which equipment repair takes place when it breaks down depends on having both current Catálogos de peças em PDF and technical diagrams, which are easy to access. Every mechanic, from beginners to experienced industrial technicians, and do-it

Everything you need to know about accessing, utilizing, and optimizing the value of digital parts catalogs and technical diagrams will be covered in this extensive guide.

You'll learn how to optimize your workflow and return to your core competencies by comprehending the various types of diagrams and identifying the most trustworthy sources. And you can encontre aqui seu manual e diagramas Catálogo em PDF e diagramas para máquinas e veículos.

Understanding Different Types of Parts Catalogs and Technical Diagrams

- Exploded view diagrams and their applications in assembly/disassembly

- Electrical wiring diagrams and schematic interpretations

- Hydraulic and pneumatic system diagrams

- Cross-sectional technical drawings and cutaway views

- Interactive digital catalogs vs. static PDF formats

- OEM (Original Equipment Manufacturer) catalogs vs. aftermarket alternatives

- Parts numbering systems and identification methods

How to Access and Download Manuals and Electrical Diagrams

- Official manufacturer websites and their digital libraries

- Third-party catalog aggregators and their reliability

- Subscription-based technical database services

- Free vs. premium catalog access options

- Mobile apps for on-the-go diagram access

- Offline storage solutions for field technicians

- Legal considerations when downloading copyrighted materials

How to Teach Employees to Utilize Digital Catalogs More Effectively

The success of introducing digital parts catalogues depends on how effectively your team utilizes them. Instruction on using interfaces, searching by part numbers or diagrams, and downloading pertinent files should all be covered in staff training.

Instruct technicians on how to differentiate between OEM and aftermarket part listings and how to read different kinds of diagrams. Diagnostics can be accelerated in the field by promoting the frequent use of mobile or tablet-based catalogues.

Errors and repair times are reduced when employees are proficient with these tools, particularly in high-stakes situations.

Digital Catalog Navigation: Finding Your Manual and Diagram Efficiently

- Search functionality and advanced filtering options

- Model number identification and cross-referencing

- Year and serial number lookup systems

- Category browsing vs. direct search methods

- Bookmarking and favorites management

- Multi-language catalogue options

- Print-friendly formatting and download options

Machinery and Vehicle-Specific Catalog Resources

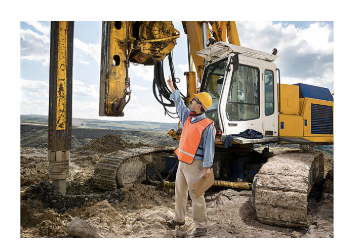

- Construction equipment parts catalogues and maintenance diagrams

- Agricultural machinery technical documentation

- Automotive repair manuals and wiring diagrams

- Industrial equipment schematics and part breakdowns

- Marine engine diagrams and parts identification

- Aviation maintenance manuals and technical illustrations

- Heavy truck and commercial vehicle resources

PDF Catalog Management and Organization Best Practices

- File naming conventions for easy retrieval

- Cloud storage solutions for catalogue libraries

- Version control and update management

- Collaborative sharing with team members

- Mobile device compatibility and viewing options

- Backup strategies for critical technical documents

- Integration with the work order management system

Troubleshooting Common Catalog and Diagram Issues

- Dealing with outdated or discontinued part numbers

- Resolving compatibility questions between different model years

- Understanding superseded parts and replacement options

- Interpreting technical symbols and abbreviations

- Quality assessment of third-party diagrams

- Verification of part specifications and dimensions

- Handling missing or incomplete documentation

Diagrams' Function in Solving Odd Problems

Sometimes, issues go beyond normal wear and tear, such as minor hydraulic failures or sporadic electrical problems. Access to comprehensive hydraulic or electrical schematics becomes crucial in these situations.

With the help of these documents, technicians can precisely trace circuits, check connections, and validate pressure pathways. They also aid in differentiating between wiring or programming problems and part failure.

Without these tools, technicians frequently have to rely on guesswork, which can be expensive and time-consuming.

Advanced Features in Modern Digital Catalogs and Technical Diagrams

- Augmented reality (AR) integration for part identification

- Interactive 3D models and virtual assembly guides

- Real-time inventory checking and pricing

- Direct ordering capabilities from catalogue interfaces

- Integration with ERP and maintenance management systems

- Multilingual support and automatic translation features

- Mobile scanning for quick part identification

Advantages of Establishing an Ecosystem for Digital Documentation

A centralized digital ecosystem offers long-term operational value for schematics and parts catalogues. It facilitates remote access from multiple devices, allows for real-time updates, and reduces dependency on outdated printed manuals.

When everyone is using the same current resources, teams can work together more successfully. Record-keeping, scheduling, and compliance reporting are all improved by incorporating documentation into ERP or maintenance platforms.

This shift to digitalization eventually increases the effectiveness of troubleshooting and standardizes repair procedures across teams and locations.

Cost-Effective Strategies for Accessing Premium Catalog Resources

- Evaluating subscription vs. pay-per-use models

- Group purchasing and shared access arrangements

- Educational discounts and training program benefits

- Free trial periods and their limitations

- ROI calculation for catalogue investment decisions

- Alternative sources for hard-to-find documentation

- Building relationships with equipment dealers and distributors

Future-Readiness: Developments in Technical Documentation

As digital technology advances, technical documentation is changing quickly. 3D interactive models, AI-powered troubleshooting assistants integrated into digital catalogues, and augmented reality (AR) overlays for real-time part identification are examples of emerging trends.

Technicians can now order parts straight from the diagram interface thanks to tighter integration between manuals and e-commerce platforms.

Anticipate the market to be dominated in the coming years by even more user-friendly platforms with improved mobile compatibility and predictive maintenance recommendations.

Conclusion: About complete catalog of parts and diagrams

Technical diagrams and parts catalogs don't have to be intimidating. You can create an extensive digital library that saves time, lowers errors, and maintains the efficiency of your business with the correct strategy and tools.

Finding trustworthy sources for your complete catalog of parts and diagramsand creating effective procedures for managing and accessing these vital resources are crucial.

Whether you're downloading manuals for immediate troubleshooting or building a reference library for future projects, the strategies we've covered will help you work smarter, not harder.

Ready to revolutionize your parts identification and maintenance processes? Start by identifying your most frequently used equipment types, and begin building your digital catalogue library today.

Related Questions

What distinguishes schematics from exploded view diagrams?

Exploded view diagrams, which are perfect for assembly and disassembly, illustrate how components physically fit together. Similar to wiring or hydraulic diagrams, schematics describe how systems work and how mechanical or electrical components interact.

Where can I locate online OEM diagrams and manuals?

Begin by visiting the manufacturer's official website or digital library. Apps, subscription databases, or reliable third-party aggregators might provide access if that isn't available. Verify authenticity and legality before downloading.